Camberwell HOuse

Denmark Hill

Tim Gaudin

At Make Bespoke Studio, we had the pleasure of collaborating with the exceptionally talented team at Tim Gaudin Joinery on a truly unique commission for a private residential client. The brief was to create a standout utility cupboard unit—elegant yet robust, and highly functional—with glazed curved brass doors forming the focal point.

The design concept was driven by Tim Gaudin, whose deep understanding of joinery and architectural detail laid the foundation for the piece. Their workshop developed the initial design vision for the brass doors—gracefully curved, glass-fronted, and seamlessly integrated into a beautifully crafted utility room. Once the design was finalised, we took on the challenge of translating it into a fully realised brass structure, engineered with precision and polish.

A Material with Character—and Complexity

Brass is a stunning material, rich in warmth and character, but it comes with its own set of technical challenges—particularly when it comes to welding. With its relatively low melting point and tendency to overheat, brass can burn easily during the fabrication process. Great care must be taken not only in welding but also in handling and polishing to ensure a consistent finish throughout.

The client had chosen new taps in a particular tone of brass, which became a key reference point. We colour-matched the brass for the cupboard frame to ensure absolute harmony across the space. Consistency in tone and sheen was essential, especially as the unit would sit prominently within the utility room.

Designing and Making: Precision from Paper to Workshop

Before anything could be made, we meticulously drew out the brass framework, complete with curves, glazing rebates, and fixing points, and submitted it for design approval. From there, we began the process of cutting each brass section to size, using CNC and hand-finishing methods to prepare the components for welding.

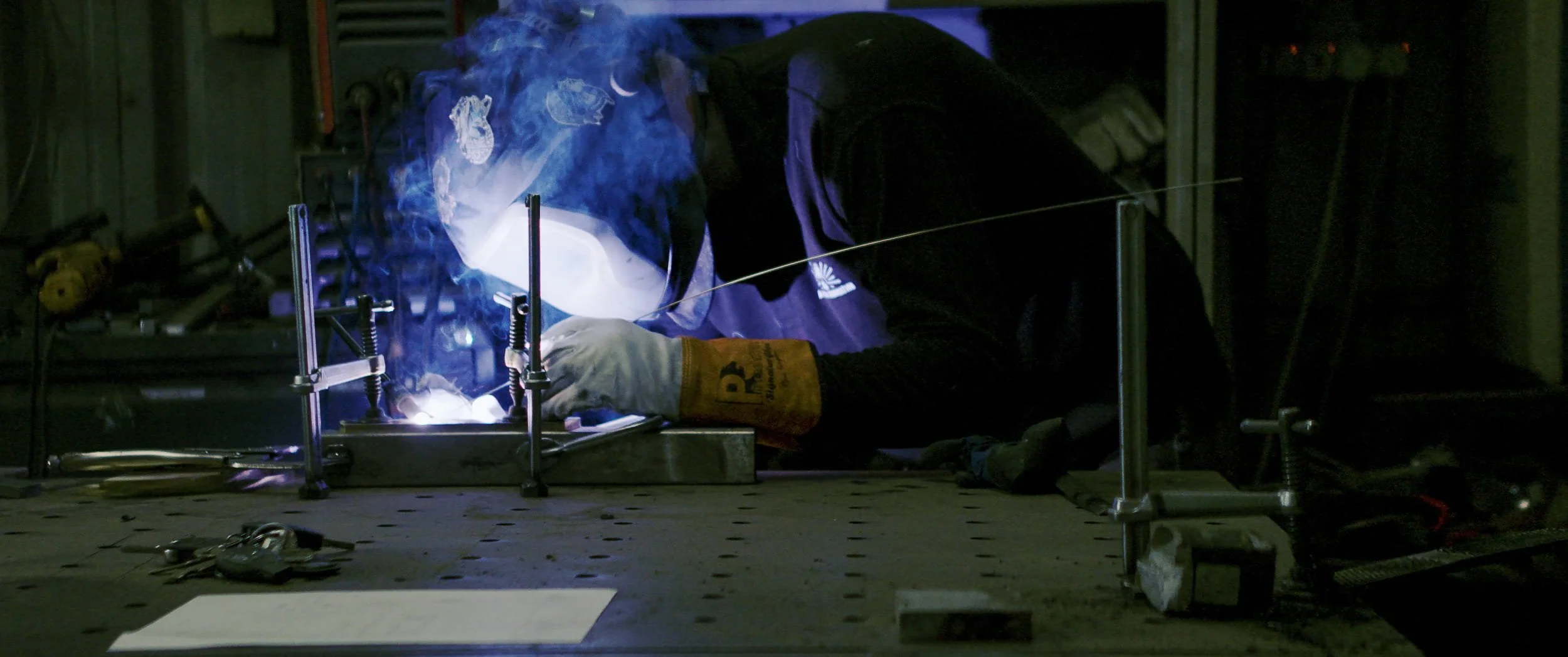

Welding brass is, by nature, a delicate operation. It requires expert control of temperature and timing to avoid oxidation and distortion. Our metalworkers approached each weld with a combination of patience, precision and care, avoiding burn-through while ensuring structural integrity. The curved glazed doors were particularly complex—bending the brass to the correct radius without kinking or discolouration was no small feat, and required both specialised tooling and a steady hand.

Bespoke Brass Worktops

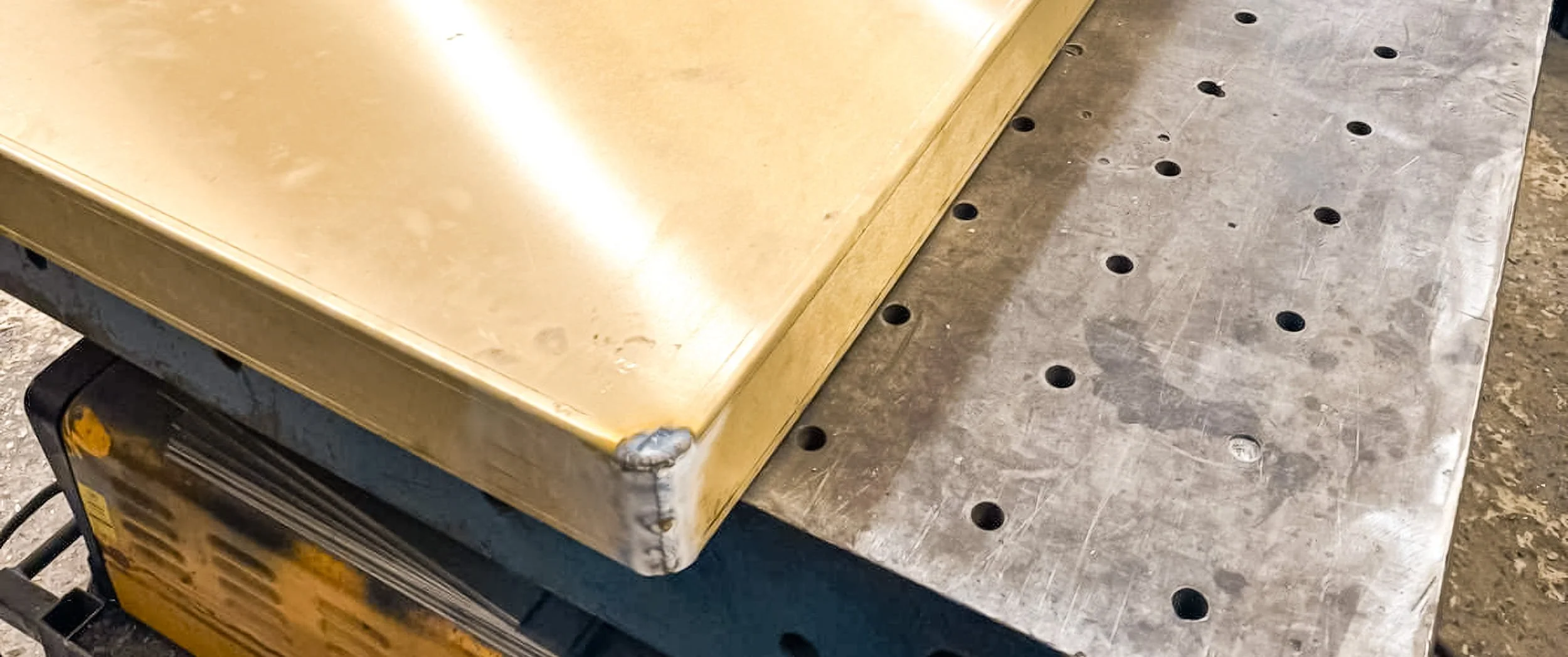

Alongside the cupboard unit, we also created the brass worktops, designed to provide a seamless and durable surface. To achieve this, we wrapped brass sheets over moisture-resistant MDF substrates, ensuring the exact dimensions were achieved while also accounting for the thickness of the brass itself.

This method allowed us to create perfectly flush surfaces and crisp edges, with the underlying MDF giving structural rigidity and the brass providing a luxurious, reflective skin. The combination strikes the ideal balance between technical performance and aesthetic refinement—hardwearing enough for daily use, yet undeniably elegant.

Polishing, Finishing, and Installation

Once assembled, the entire brass structure and worktops underwent a thorough polishing process to achieve an immaculate, high-gloss finish. Every weld, every corner, every curve had to be flawless. We take pride in our bespoke metalwork expertise, and this project was a true showcase of what’s possible when technical precision meets craftsmanship.

Installation was a collaborative effort between our team and Tim Gaudin Joinery. We worked closely onsite, making fine adjustments to ensure the brass unit sat perfectly within the space. Only once every detail was aligned did we carefully insert the bespoke curved glass panels, completing the unit.

Living with Brass

One of the most beautiful aspects of brass is its versatility over time. Clients can choose to maintain a mirror-polished finish, keeping the metal bright and reflective with regular polishing. Equally, brass can be left to naturally patinate, developing a rich, organic character as it darkens and softens with age. Left unpolished, the brass gradually takes on deeper tones of ochre, bronze, and even subtle verdigris highlights—a living finish that tells its own story and only enhances the sense of craftsmanship.

This project highlights what can be achieved when designers, joiners, and metal fabricators work in harmony. The result is a refined, contemporary statement piece that elevates the entire room—functionally and aesthetically.

If you're looking to incorporate bespoke brass elements into your next interior project, from architectural detailing to freestanding pieces, we’d love to help bring your vision to life.